Arzon to'ldirish qadoqlash kavanozi asalni to'ldirish mashinasi

1. Avtomatik asal to'ldirish mashinasi

NP-VF avtomatik asal to'ldirish mashinasi viskoz asalni shisha idishlar va uy hayvonlari uchun idishlarga to'ldirish uchun maxsus ishlab chiqilgan bo'lib, u shuningdek asal to'ldiruvchisi, asal idishini qadoqlash mashinasidir. Bu asalarichilik zavodi uchun ideal tanlovdir.

2. Different types of VKPAK automatic honey filling machine

Turli xil quvvatga ega asal to'ldirish mashinasi bazasining ko'plab modellari va turlari mavjud, to'ldirish nozullari soni bir boshdan 16 boshgacha va to'ldirish hajmi 5 g dan 20 g gacha, va 100 g dan 1000 g va hatto 1000 g dan 5 kg gacha.

3. Asal to'ldiruvchining asosiy tuzilishi

-20 dan 200 litrgacha Variant uchun ustki bunker, ikkita ko'ylagi bilan bunker isitish va aralashtirish tizimi variant uchun,

- 304SS tomonidan ishlab chiqarilgan mashinaning asosiy tanasi

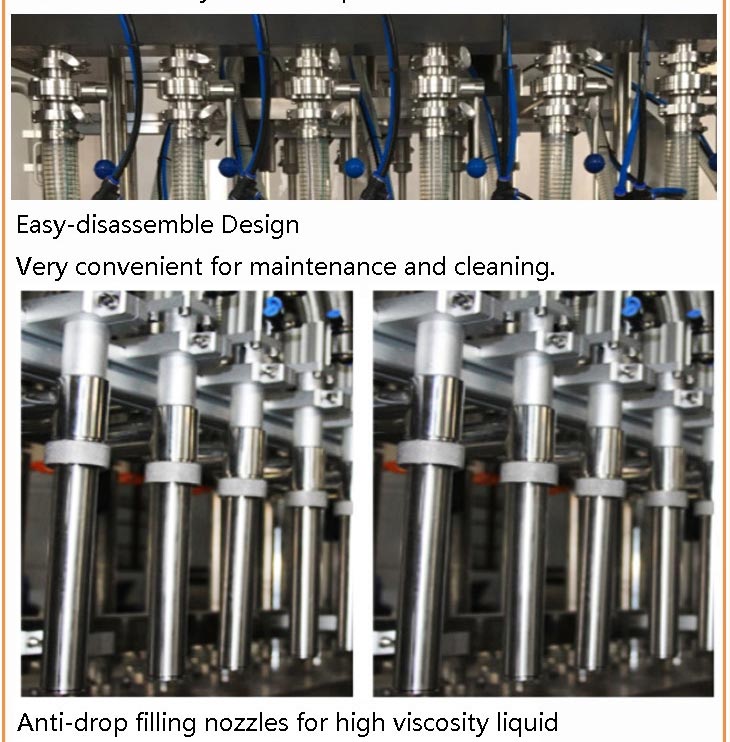

- To'ldirish nozullari, to'ldirish nozullari maxsus ishlab chiqilgan o'chirish va asal uchun ipak kesilgan

- Havo tsilindri bilan yuqoriga va pastga harakatlanadigan to'ldirish nozullari va variant uchun servo vosita yuqoriga va pastga harakatlanadi

-PLC boshqaruv tizimi va HMI ishlashi

-Asal uchun maxsus tayyorlangan ot va klapan, CIP tizimi bilan otni ulang.

4. avtomatik asal to'ldiruvchining raqobatbardosh afzalligi

Avtomatning ko'plab afzalliklari bor asal to'ldirish mashinasi

-PLC boshqaruvi, sensorli ekranda ishlash.

-Panasonic servo dvigateli, HMI-da to'ldirish hajmini avtomatik ravishda sozlash, masalan. Foydalanuvchilar 500 g asalni to'ldirishni xohlashadi,

foydalanuvchilar shunchaki 500 raqamini kiritadilar, keyin mashina avtomatik ravishda sozlanadi

-bu piston bo'yicha volumetrik, yuqori to'ldirish aniqligi

- Yuqori bilan Asalning kristallanishini oldini oladigan ikki qavatli isitish va aralashtirish tanklari bir kun yoki undan ko'proq kun ishlashni to'xtating. Bundan tashqari, piston va shlangni isitish mumkin.

-Asalni avtomatik to'ldirish mashinasi foydalanuvchilarni CIP tizimini bog'laydigan CIP tizimi funktsiyasiga ega bo'lishi mumkin

-Asal to'ldiruvchining oti asal tabiatiga ko'ra maxsus tayyorlangan, o'lik burchaksiz, oziq-ovqat darajasi

- Asal to'ldiruvchisidagi yumshoq naychalar yoki quvurlar jahon brendiga moslashtirilgan Toyox Yaponiyadan

-Asalni yopishqoq o'tkazish uchun maxsus ishlab chiqarilgan aylanma valf

5. Asosiy texnik

| Burunlarni to'ldirish | 1-16Nozzles |

| Ishlab chiqarish hajmi | Bir soatda 800-500000 shisha |

| To'ldirish hajmi | 100-500ml, 100ml tp 1000ml |

| Quvvat | 2000 Vt, 220VAC |

| Aniqlik | ± 0,1% |

| Haydalgan | Panasonic Servo Motor |

| Kirish | Schneider sensorli ekrani |

6. Avtomatik asal to'ldirish mashinasi Asosiy xususiyatlar

a) To'ldirish uchun mahsulotlar:

1) issiq to'ldirish (35 ~ 40 ℃), sovuq to'ldirish normal harorat

2) solishtirma tortishish: 1,1 ~1,4 gr/sm3

3) Shokoladli pastani yoyish • Asal • Spreading pishloq pastasi, melas.

b) shisha turi:

1) PET shisha • Kvadrant ko'ndalang kesimi • Hajmi 250 ml. • bo'yin 32 mm.

2) Shisha bankalar va pe, PET bankalar • Silindrsimon kesma • Hajmi 200 ~ 350 ml.

3) bo'yin 45 mm.

c) To'ldirish tolerantliklari: +/- maksimal 0,5%

asal to'ldirish mashinasining asosiy tarkibi

1.1 Shisha va bankalarni havo bilan tozalash.

1.2 Avtomatik idishlarni oziqlantirish va ushlagichlar (agar kerak bo'lsa, plastik butilkalar uchun)

1.3 Tomchilamaydi.

1.4 Chiqish 20 ~ 100 zarba/daq.

1.5 Shisha yo'q To'ldirilmaydi

1.3 PLC sensorli ekranli boshqaruv paneli. Malty to'ldirish dasturlarini saqlash.

1.4 Ikkita ko'ylakli bunker bilan:

• 180 litr hajm, • Darajani detektori. • Elektr isitgichlar.

• Mahsulotning harorat detektori va nazorati • Aralashtirgich

1.5 To'ldirish tizimi va nozullarni tozalash uchun oson qismlarga ajratish.

1.6 Mashinaning korpusi SS 304, mahsulot bilan aloqa qiladigan barcha qismlari SSL 316.

Bizning mashinamiz boshqa etkazib beruvchilarga qarshi

| Mahsulot | Bizning mashinamiz | Boshqa etkazib beruvchilar |

| Yuqori tank | Ikki ko'ylagi elektr isitish tanki | YO'Q |

| Piston | Issiq suvli velosiped isitish tizimi bilan | YO'Q |

| Quvur va shlangni ulang | Issiq suvli isitish tizimi bilan | YO'Q |

| To'ldirish uchun nozullar | O'chirish va ipakka qarshi to'ldirish nozullari | YO'Q |

| CIP tizimi | Bizning mashinamiz CIP tizimini ulashi mumkin | YO'Q |

Bizning xizmatlarimiz

O'rnatish va nosozliklarni tuzatish

- Agar so'ralsa, biz uskunani xaridorning joyiga o'rnatish va disk raskadrovka qilish uchun muhandislarni yuboramiz.

- Xalqaro ikki tomonlama aviachiptalar, turar joy, ovqatlanish va transport, tibbiy xarajatlar Xaridor muhandislar uchun to'laydi.

- Nosozliklarni tuzatishning odatiy muddati - 3-7 kun, xaridor har bir muhandis uchun kuniga 80 AQSh dollari to'lashi kerak.

-- Agar mijoz yuqorida talab qilmasa, mijoz bizning fabrikamizda tayyorlanishi kerak. O'rnatishdan oldin mijoz birinchi navbatda foydalanish qo'llanmasini o'qib chiqishi kerak. Ayni paytda, v

e mijozga operatsiya videosini taklif qiladi.

O'qitish

- Biz mashinalarni o'qitish tizimini taklif qilamiz; mijoz fabrikamizda yoki mijozlar ustaxonasida o'qishni tanlashi mumkin. Oddiy mashg'ulot kunlari 1-2 kun.

Kafolat

- Sotilgan mashina bir yilda kafolatlanadi.

- Kafolat yilida etkazib beruvchining sifati buzilganligi sababli buzilgan ehtiyot qismlar xaridorlar uchun bepul etkazib beriladi, mijoz posilka og'irligi 500 grammdan oshsa yuk narxini to'lashi kerak.

- Eskiradigan ehtiyot qismlarning kafolati muddati tugamaydi, masalan, uzuklar, kamarlar singari jihozlar bir yil davomida foydalanish bilan ta'minlanadi.